Desarrollo Farmacéutico

Liberación de Lotes – QC / QP

Docuchem offers to companies holding MA within the EU services for:

Even when the ultimate responsibility for the performance of a medicinal product over its lifetime, its safety, quality and efficacy, lies with the marketing authorisation holder (MAH), the later can contract an outside testing laboratory and the services of its QP to become responsible for ensuring that each individual batch has been manufactured and checked in compliance with laws in force in the Member State where certification takes place, in accordance with the requirements of the Marketing authorisation (MA) and with Good Manufacturing Practice (GMP).

The QPcertifying the finished product is responsible for ensuring that each finished medicinal product batch has been manufactured in accordance with GMP and the MA. Unless an MRA or similar agreement is in place between the EU and the exporting country, the QP is also responsible for ensuring that the finished medicinal product batch has undergone in a Member State a full qualitative analysis, a quantitative analysis of at least all the active substances and all the other tests or checks necessary to ensure the quality of medicinal products is in accordance with the requirements of the MA

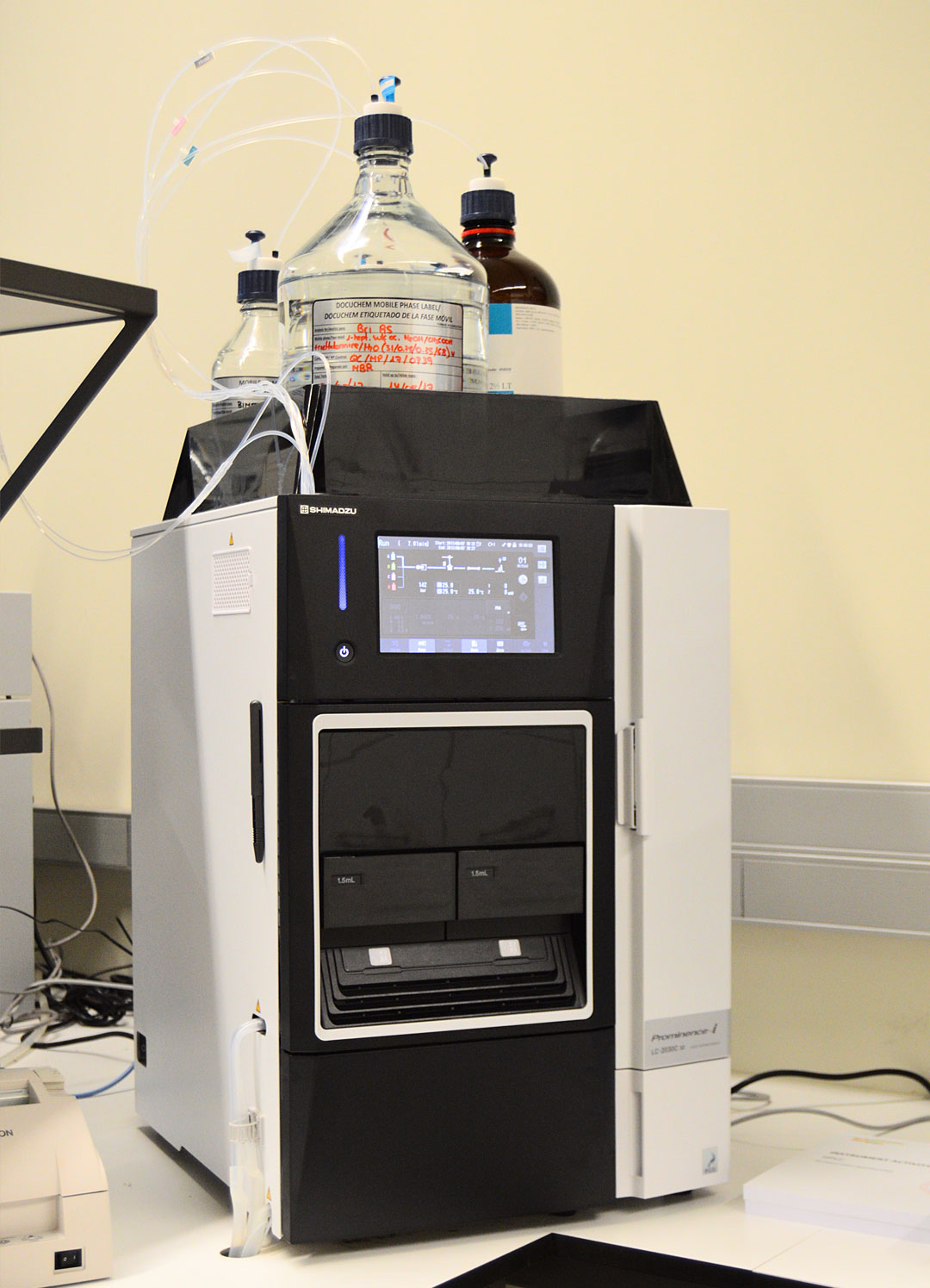

The process of batch release comprises of the following actions that need to be executed in a EU_GMP authorised Quality control lab and approved by a QP within the EU for products manufactured in a nonEU-member state:

i.The checking of the manufacture and the actual qualitative and quantitative testing of the batch in accordance with defined release procedures as described in the MA.

ii.The certification of the finished product batch signifying that the batch is in compliance with GMP and the requirements of its MA. This represents the quality release of the batch.

iii.The transfer to saleable stock, and/or export of the finished batch of product which should take into account the certification performed by the QP.